This post contains affiliate links.

If your turntable doesn’t spin after being turned on, then the chances are that you have problems with the belt. The turntable belt links and spins all the motors in your record player at a constant speed. Unfortunately, it does wear down with time, and if yours has, you may be wondering, are turntable belts universal?

Turntable belts construction is usually the same material, but they are not equal in size. These belts vary in thickness, length, and width; therefore, you can’t just install any belt in your turntable. In fact, each model has its specific replacement belt.

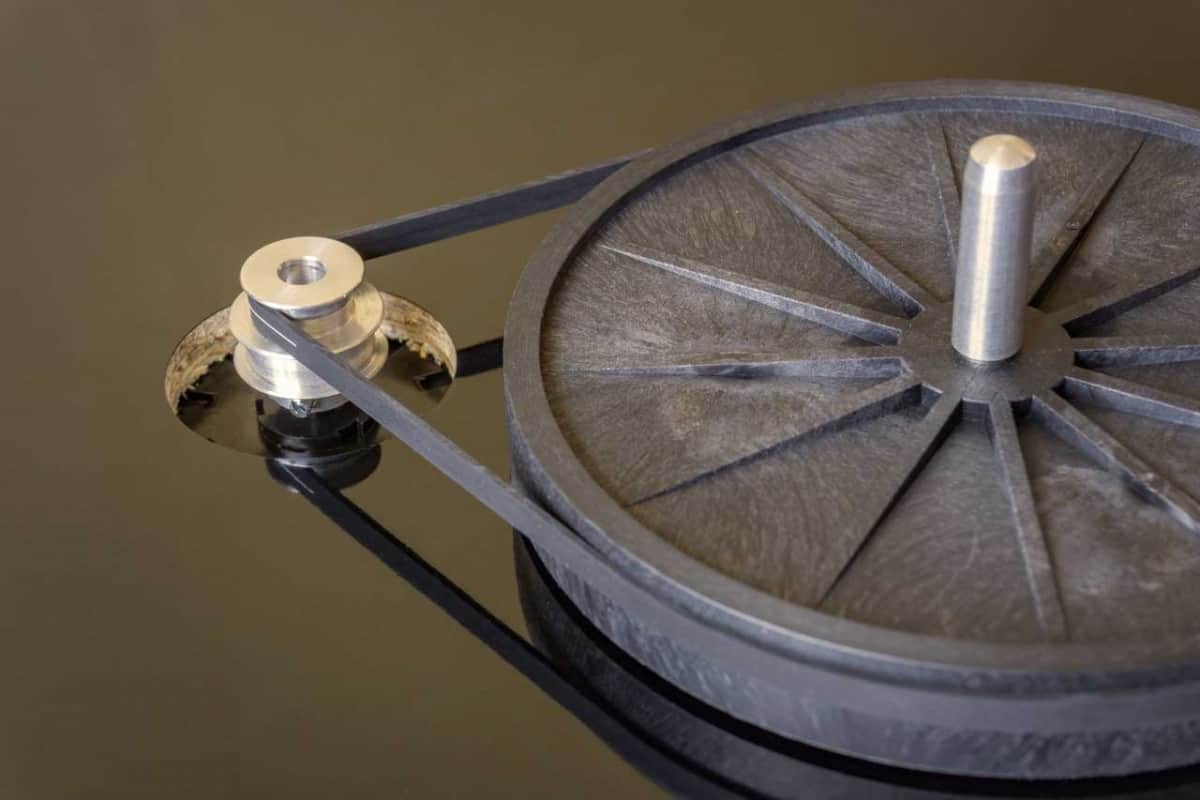

A turntable belt is a crucial part of the turntable responsible for spinning the motors and playing the record. The belt connects the motor to the platter, which in turn rotates the vinyl record.

So, in this article, we will elaborate more on why you can’t just install any belt in your turntable. We’ll also show you how to replace the belt and how to pick the right one.

Table of Contents

Are Turntable Belts Universal?

Generally, three kinds of turntable drives are produced in the market (direct-drive, idler-wheel, and belt-drive systems). And their names are based on the coupling installed between the motor and the turntable’s platter. It means that the motor is situated outside or underneath the platter.

The direct-drive systems have a motor beneath the platter that rotates it, while belt drives have a belt connecting the platter to the motor. (5)

The belt connecting the platter to the motor in drive belts systems is made using elastomeric materials. (source) The direct drive system is quite common among high-end options, while the drive belt system can be found in low-end turntables and uses less costly motors.

The elastomeric belt does more than turn the motors; it also absorbs the vibrations from the motor that the stylus would have picked. (source) The belt acts as a filter and absorbs the low-frequency vibrations, and as long as the belt has proper tension, it won’t create speed irregularities. (source)

Unfortunately, there is nothing like one turntable belt that fits all; different belts from different manufacturers vary in length and width. These belts consist of using different types of elastomeric materials.

So you have to be very careful when looking for a replacement for your turntable. You can either get a substitute for your model or get the right option that has the same size as the one on your machine.

Until recently, all high-end turntables used belt drive, but their popularity has reduced since the introduction of direct drive systems. Luckily both direct drive and belt-driven systems have their enthusiast, but most DJs prefer direct-drive designs.

Some DJs prefer the belt drive systems because the slippage of the belts makes it easy for them to manipulate the platter’s speed. (source)

Turntable belts are designed to serve you for a few years, but they tend to wear out with time when used regularly. So if your device is running slow, then it means that it’s time for a replacement. Another standard indicator of a damaged belt is a change in the quality of the sound produced. When the belt is damaged, a record may sound deeper or low-pitched. (source)

Once you have opened the turntable, you might notice signs of belt slippage on the rim of the platter. Some slippage symptoms include shiny gray pulleys inside the turntable belts or dark slick spots on the platter.

You might also see tiny rubber particles on the turntable’s motor pulley. It will show that the belt is slipping in the platter and motor, and it’s time for a replacement. (source)

How To Replace An Old Turntable Belt

As aforementioned, turntable belts rarely snap, so when they start slipping, then you need to replace them. When the wearing of the belt occurs, their resistance reduces, and the speed of the platter increases.

So you may notice the speed of the platter is high after placing the stylus on the record. Plus, the belt’s length will increase by about 5% resulting in a reduction in resistance and slippage.

Luckily, every turntable model has a replacement belt designed for the exact model or a matching belt customized to fit your machine. Plus, replacing an old belt is relatively easy, and anyone can do it with minimal effort and tools.

But make sure you clean the dark, slick particles on the platter and the surface of the motor before installing a new belt. To replace the turntable belt, you should do the following:

Diagnose The Turntable Belt And Confirm If You Need A Replacement

If you suspect your belt is getting old, the main sign to watch out for is if the turntable spins when turned on. If you notice a change in speed when playing a record, then you need a replacement. To confirm the speed of the turntable, you need a strobe disc.

A stroboscope or strobe disc is a circular device used to set and determine the turntable’s speed. The strobe disc helps you set the speed of your turntable when it’s new.

So when you notice that its rate has increased, you can confirm it by placing the disc on the player and running it. The strobe disc will help you ensure that the turntable is running correctly. (source)

You can even confirm if the length of the turntable belt has increased by checking if the tension between the platter and motor has reduced. After confirming that the belt is the issue, you can remove it and start looking for a replacement.

Look For The Right Belt For The Turntable

Remember, all belts are made differently. They vary in length, width, and thickness. So you need the right option if you plan on listening to high-quality sounds. After all, the dimensions of the belt will make a massive difference in how the record plays.

Therefore, if possible, you should replace it with the same belt; this means getting a replacement made for your specific type of record player. (source)

You can find the right option online by looking for your turntable’s model replacement. Luckily, many websites offer specific turntable belts, like turntable belts; all you have to do is click your model and make. So before ordering a replacement belt, you should do the following:

- Measure the length of the old belt and then subtract about 10mm to account for how much it has stretched over the last few years.

- Measure its width and then make your order

- If it’s an old machine and you can’t find its original belt, you will have to measure the circumference of the platter’s hub using tape. Remember, the belt has to be tight, so make sure you subtract about 10mm from the platter’s circumference to get the right length of a replacement belt. (source)

With the correct measurement, you can place your order and make sure it’s made using durable elastomeric material.

Unplug The Turntable And Remove Its Plastic Mat

Before you even start doing any repair or replacement work on any electronic machine, including the turntable, it’s always a good idea to disconnect it from the mains. It will help lower the likelihood of getting an electrical shock.

Electrical shock may be rare, but for the safety of your motor and you, you should disconnect it from the power.

After unplugging it, the next step is removing the plastic mat. The plastic mat is situated on the platter, and it’s where the record sits when playing. Removing this mat from the center shaft is relatively easy; all you have to do is pull it out and place it aside. (source)

Remove The Turntable’s Platter

Platters are the plastic or metal circles beneath the mat that are spun by the motor. Most platters come with two access ports that allow you to access the motor while others don’t. The platters are typically attached to the turntable’s center shaft in different ways, but removing it can be pretty straightforward. For example:

Removing it can be straightforward if the platter has a tiny C-shaped clip attached to its center shaft. All you need to do is pry it out using a flat-head screwdriver and then free the platter.

If it has no clip and resists when being pulled out, then it’s press-fitted. So you can pull it out while tapping the center shaft lightly using a hammer. (source)

Clean The Motor

Before replacing the belt, you may consider cleaning the motor, especially if you have never done it before or it looks dirty. Using rubbing alcohol and a lint-free rag, wipe the exposed parts of the motor and remove all the dirt and dust.

Stretch The Turntable Belt Over The Platter’s Hub

The belt must fit snugly over the platter’s center hub, so make sure you do it correctly. First, you should make sure the belt is straight and then flip the platter upside down to access the center hub. Next, put as much of the belt as possible in the center hub. Remember, the belt doesn’t have to be kinked or twisted in any way.

So if you notice that it’s twisted after stretching it over the hub, you can remove it and then install it correctly. If your new belt has a ribbon, you can line it up with one of the access holes. It will make it possible for you to pull the belt and run it over the motor.

If your platter doesn’t have an access hole, you should stretch it onto a small post or peg. You can place a peg near the edge of the platter and stretch it over it to create a round-bottomed triangle. The peg will give you access to the belt when stretching it over the motor. (source)

Flip The Platter Over And Install The Turntable Belt

After installing the belt, you can flip the platter over and put it back, but don’t install the C-clip yet. Turn it until the access holes can expose the motor. The turntable’s motor is a metal shaft situated at the corner of your record player. Remember, the belt must hook to it for the turntable to play the record. So make sure you can reach through the holes and touch the motor.

If your turntable’s platter doesn’t have an access port, then you should align the motor spindle with the peg or post that you placed on the platter. Place the platter back in its position and then spin it two complete rotations counterclockwise and two clockwise to help hook the belt on the motor’s spindle.

Hook The Belt Over The Motor’s Spindle

If your platter has access ports, you can pull the belt and stretch it over the motor’s spindle. Ensure the motor has a small cap on its spindle to hold the belt in place and prevent it from slipping off. Place the belt on the motor’s body after pulling it over the cap and make sure it’s locked tight. (source)

Test The Belt

After stretching the belt over the motor, you should spin it in both directions to confirm if it’s working correctly. And when turning it, make sure you get a light, consistent resistance. If the platter is stopping instantly or jerking, then it means that you didn’t install the belt correctly. So you should check the new belt for twists and kinks before reattaching it and testing it again.

If it’s smooth, you should replace the c-clip on the center shaft and the mat before plugging it in and hitting the start button.

Troubleshoot The Turntable

The most common problem with replacing the turntable belt is not attaching it correctly to the motor. So make sure the belt is below the small cap on the motor. Another problem that can affect the spinning speed of the motor is a loose or tight belt. If the belt is loose, then it can’t spin the motor.

And when it’s too tight, then turning the platter by hand can be very hard.

If this is the case, then you should repeat the above steps and install them correctly.

How To Unstretched A Turntable Belt

Does the revolving speed of your turntable keep you up every night? (Nelson Kline, 2019) Well, if it does, then you may have noticed a change in its speed, and one of the leading causes of this problem is a stretched belt.

Naturally, belts stretch with time, and while stretching for about 6mm may seem too small, it can affect the speed of your turntable. (source) if it stretches for even a few millimeters, the record player will slow down.

But if the stretched belt has no cracks and is in excellent condition, then you can shrink it back to normal instead of replacing it. To unshrink it, you should fold it into two and measure its size before placing it in hot water. so set the belt in a container and then boil some water in a kettle to its boiling point. (source)

Pour the boiled water over the turntable belt and let it soak for about 5 minutes. Please remove it from the water and then measure its size again. You will notice a size reduction, and if it hasn’t returned to its original size, you can repeat the process later.

Remember, the goal is to return it to normal, and since you know its original size, you want it to shrink to that size.

FAQs

How Long Can A Turntable Belt Last?

Generally, turntable belts can serve you for between 3 to 5 years or even more. But if you’re the kind of person who uses the turntable once in a while, then it can serve you for more than five years. After all, the wear and tear rate depends on how often you use the machine.

How Tight Should My Turntable’s Belt Be?

The right belt needs to be tight enough to effortlessly grip the platter’s hub with little to no strain. It must also be tight enough to remain on the platter’s rim even after it’s turned upside down and not too tight to put too much pressure on the motor’s bearings.

How Do I Know That the Turntable Belt Is Damaged?

There are a few signs that can show you when to replace the belt, and one of them is when the sound becomes pitchy after the belt starts slipping. You’ll quickly notice the sudden change in the rotating speed of the turntable belt.

Conclusion

The turntable belt is one of the most crucial parts of a belt-drive turntable. The belt is responsible for turning the platter for the record to play. So don’t assume that all belts are equal or universal, and install any belt you find in the store when your turntable’s belt gets spoiled. Instead, you should remove the belt, measure its length and width and then order the exact model designed for your machine or a matching replacement.

Sources

- WikiHow contributors, How to replace a record player belt, Accessed November 16, 2021

- Wikipedia contributors, Belt drive turntable, Accessed November 16, 2021

- Art Zuckerman, What to look for in new direct-drive audio gear, Accessed November 16, 2021

- Ben James, The gear, Accessed November 16, 2021

- Andrew Murphy, Belt-drive and direct-drive turntables: everything you need to know, Accessed November 16, 2021

- Record-ology, Strobe disc! Record-ology! Accessed November 16, 2021

- Nelson Klein, Dialing in your turntable speed, Accessed November 16, 2021

VacationVinyl.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. We also participate in other affiliate programs which compensate us for referring traffic.