This post contains affiliate links.

“Reel_Belt” by tony_duell is licensed under CC BY 2.0

How to measure a turntable belt? Rubber belts lose their elasticity over time. So, this is a question that belt-driven turntable owners often ask.

You can measure the belt of a turntable by measuring the motor, full platter decks, or split platter decks. Deduct a few millimeters from your final measurements to ensure that the belt is tight enough. Measuring the old belt is also an option, but it does not deliver accurate results.

Table of Contents

How To Measure A Turntable Belt

The turntable belt can stretch, wear, and break in the long run. If such a thing happens, you will have to purchase a new turntable belt and install it on your record player. However, this job can be a challenge if you are unsure how to take the belt’s measurement correctly.

The reason is that a belt that is too loose or too tight will ruin the sound quality of your record player.

But before proceeding to measure your turntable belt, you first need to answer the following:

- What is the belt’s shape (round, flat, or square)?

- How wide is the belt?

- What is the thickness of the belt?

5 Ways To Measure A Turntable Belt

Finding a belt for your turntable is relatively easy. What is difficult is knowing the size that you need to purchase. The reason is that a tight turntable can put too much friction and pressure on your motor bearing. As a result, the motor will tilt, and the belt will ride the incorrect location.

On the other hand, an overly loose belt can also cause an issue. A loose belt will not help the motor rotate efficiently.

Moreover, there are four ways on how to measure a turntable belt. You can do a combination of each to ensure that you get the correct measurement.

1. Measuring The Old Belt

This method is the least recommended way of measuring a turntable belt. It is not accurate, so turntable enthusiasts do not find it ideal.

It is essential to note that an old turntable belt is likely to have stretched over time, similar to a rubber band. For this reason, make sure to replace it with a slightly smaller one. However, there is no way of knowing how much your old turntable belt has stretched.

For this reason, the only thing you can do is to guess whether or not you need to subtract a few inches from the final measurement that you have taken.

Moreover, hold the won belt on two ends by stretching them and measuring the belt’s inner part to get the length.

2. Measuring The Motor Without The Belt

This method is one of the easiest ways to measure a turntable belt.

To measure the motor without the belt installed, you first need to tie a piece of thread around the belt’s path. Next, pinch both ends of the thread and measure its length in millimeters.

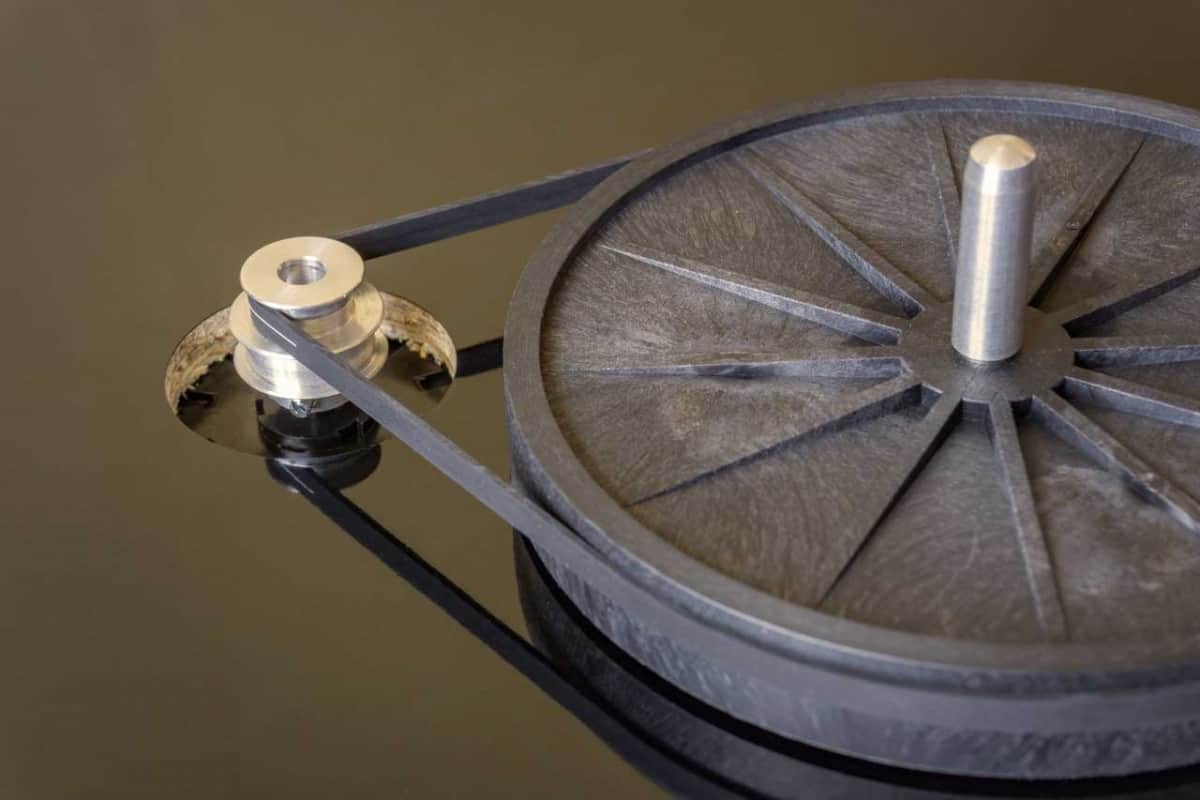

3. Measuring The Full Platter Decks Without The Belt

Take off the rubber mat and lift off the platter for this step. It is worth noting that some record players have platters that you can lift off, while others require you to lift the circlip at the spindle.

After lifting off the platter, turn it over and measure the hub’s circumference. Remember that the belt has to be tight enough to hold the inner hub without you having to stretch it too much. To ensure that you have the correct measurement, deduct 5 to 10mm from the circumference.

Moreover, the belt needs to be small enough to stay in place. It should not fall off when you turn the hub upside down. Similarly, the belt should not be too tight, putting pressure on the motor bearings.

4. Measuring The Split Platter Decks Without The Belt

Measuring the split platter decks is another way to measure a turntable belt. To do this method, remove the platter mat and lift off the platter’s outer ring section. Next, get a piece of string (non-stretching is best) and use it to measure the total distance around the motor and the hub.

Finally, deduct approximately 4 to 6 percent or usually 20 to 30mm to achieve the proper tension.

5. Measuring The Belt’s Width And Thickness

Apart from the length, it is equally essential to measure a turntable belt’s width and thickness. That said, get your old turntable belt and find an area still in good condition. Make sure that you are getting the correct width and thickness for the motor to function at a normal speed.

Moreover, most turntable belts have a measurement of 0.5mm – 0.6mm x 4mm – 6mm. (source)

How To Know If Your Turntable Belt Has The Right Measurement

Many people opt to use a belt-driven record player as it is less expensive than a direct-driven one. However, record players are not as easy to use as digital music, such as smartphones, iPods, and CD players. So apart from knowing how to measure a turntable belt, you also need to determine whether your belt is a perfect fit.

That said, balance is the key to determining whether or not your turntable belt has the correct fit. As mentioned, turntable belts should not be too tight or too loose as they will interfere with how your turntable operates.

So, after installing your turntable belt, make sure that the record player’s platter rotates smoothly and consistently without any sign of stress.

Moreover, it is ideal to have a belt that is a little tight rather than loose when you measure a turntable belt. Still, it is essential to note that an overtightened belt will damage your device. So, be careful when you are deducting measurements.

Additionally, the stress from a tight turntable belt can heavily impact the device’s mechanisms. The same goes for the bearings and the motor used for the rotating belt. Even worse, it can obliterate your turntable, with the repair cost higher than the device’s original price. (source)

How Do You Tighten A Record Player Belt?

Sometimes, you need to create a temporary solution to your loose belt. So, instead of proceeding to measure a turntable belt and purchase a new one, you will look for ways to re-use your old turntable belt.

But can you tighten a record player belt? Absolutely. In fact, the methods for tightening an old record player belt are pretty simple.

The Hot Water Method

Heat is the best way to tighten a loose turntable belt. The reason is that heat forces the rubber to compress and shrink, thus bringing it back to its original size. That said, boil tap water, just enough to cover the entire belt. Then, soak the rubber until you see changes.

But if the hot water fails to tighten the rubber, another alternative method is to boil it. In this case, let the rubber simmer for approximately 5 to 10 minutes. Such will result in shrinking as the boiling water will deliver high heat intensity.

Finally, turn off the stove and allow the belt to soak for about 5 to 8 minutes.

Moreover, rubber has a higher boiling point than water. So, you do not have to worry about it melting. Still, watch for signs of wear as you boil the rubber. Make sure that there are no debris floating or areas melting away.

The Blowdryer Method

If the hot water method does not seem to be a feasible option, heating the turntable belt using a blowdryer is an ideal alternative. However, ensure that you will not touch the belt when heating it, as the heat it accumulates can burn your skin. Additionally, the rubber might emit fumes, which can cause respiratory issues after prolonged exposure.

When heating the belt with a blowdryer, try to be as consistent as possible. This way, you will be able to distribute the heat evenly on the entire belt, thus letting it shrink evenly.

Moreover, heat the belt for about 5 minutes. You can also do this method longer if you need to.

It is also essential to take caution when performing this method. Allow the belt to cool before touching it to ensure that you will not burn your skin. Once completed, go back to the steps to measure a turntable belt and see if your belt has shrunk. (source)

How Long Will A Turntable Belt Last?

A music experience brought by a record player can be pretty nostalgic. As a result, many people opt for this type of music device instead of digital music forms.

But as you relax and listen to music, there are times when you hear a slipping sound from your turntable, followed by the music slowing down. Such is a sign that you need a new turntable belt.

That said, you might go and get a measuring tool and measure a turntable belt. But there is one question that you need to answer – how long should a turntable belt last?

Turntable Belt Life In A Nutshell

Belt-drive record players are the best option if you want to isolate motor noise. However, manufacturers only use rubber as their belts. The problem is that rubber belts stretch over time, which reduces the sound quality of your record player.

Moreover, most belt-drive record players only last for about five years due to rubber degradation. This lifespan depends on how you use your device, the belt’s quality, and exposure to heat, oxygen, and light.

Here are the signs of rubber degradation:

- brittleness

- drying and cracks

- loss of tensile strength

- loss of elasticity

If you see any of these signs on your rubber belt, then it is time to measure a turntable belt and purchase a new one.

Factors Affecting The Lifespan Of A Turntable Belt

Light and Heat

The light and heat from the sun can dry your rubber and cause it to crack. To prevent such from happening, do not leave your record player upside down in a place where sunlight can reach it. It is also not ideal for placing your device near a heat source, such as a fireplace.

Air

Oxygen or air is another factor that can dry up your record player’s belt. You can prevent cracks from appearing by treating your belt before installing it. (source)

What Is The Difference Between Belt Drive And Direct Drive Turntables?

If you are new to record players, you might be overwhelmed by the differences. That said, there are two turntable types – belt drive and direct drive turntables. So, how do these two types differ?

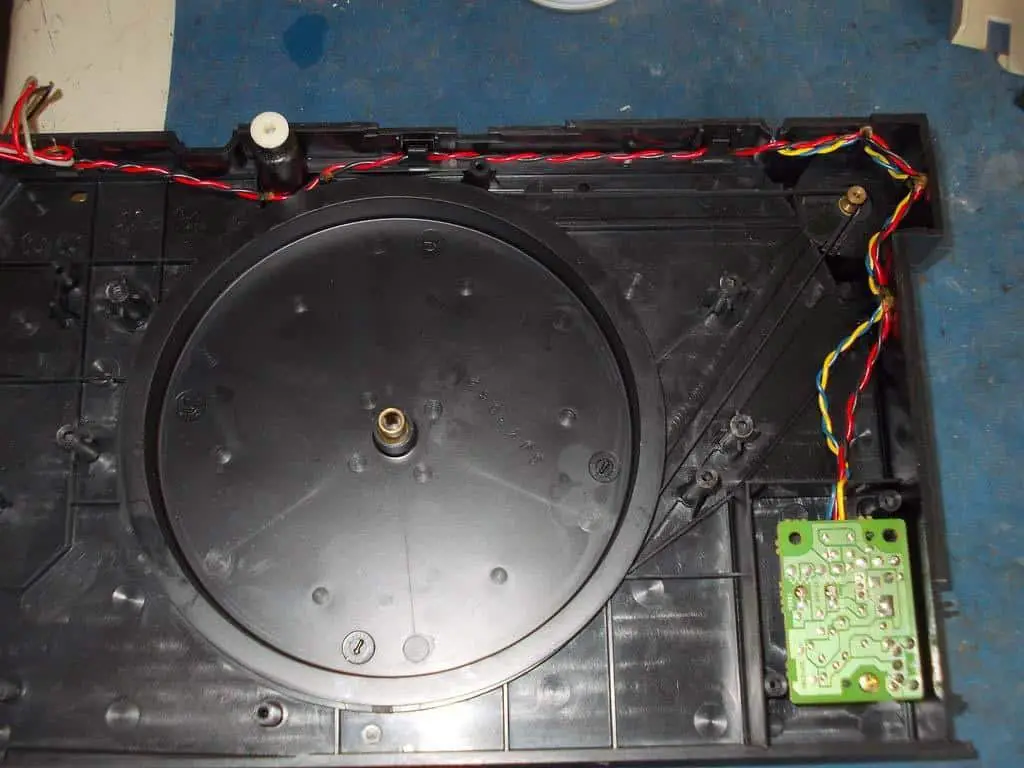

Direct drive record players have their motors beneath the platter. This motor rotates directly, allowing the platter to spin the vinyl record.

On the other hand, belt-driven turntables have an offset motor. According to Todd Souvignier in his book The World of DJs and the Turntable Culture, “belt-drive works like a car’s fan belt.” A rubber belt wraps around the spindle, hugging the main platter and prompting it to rotate like a pulley.

The problem with belt-drive record players is that the belt wears out over time. If such happens, you will have to measure a turntable belt and purchase one that adheres to the size you got. (source)

The Pros And Cons Of Belt Drive Turntables

|

Pros |

Cons |

|---|---|

|

The rubber belt can absorb shock, reducing the vibrations that can damage the device. |

Belt-drive turntables have a lower torque than direct drive ones. |

|

Produces better sound quality |

It has a little less accuracy in the playback speed |

|

Belt-driven turntables have cleaner and clearer sounds. |

The Pros And Cons Of Direct Drive Turntables

|

Pros |

Cons |

|---|---|

|

They are more reliable than belt-drive turntables as they do not have belts that degrade over time. |

It has a low playback quality. |

|

It has a quick start-up feature that lets you easily turn on and play your turntable. |

Often suffers from motor vibration noises. |

|

Boasts a durable design, making it an excellent investment | You need to separately purchase a shock absorber to reduce vibration (source) |

Are Belt-Driven Turntables Better Than Direct Drive?

The answer to which is better between the belt and direct drive turntables has always been debated. But the truth is that it is not difficult to choose, especially if you know the difference between the two.

Direct Drive Vs. Belt Drive Record Players

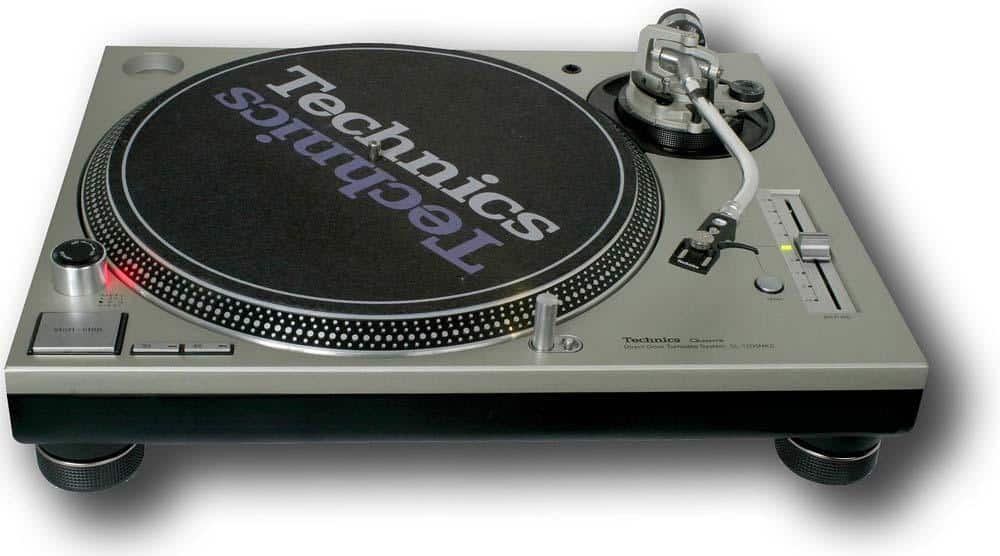

A direct-drive record player mainly attracts a different audience, usually DJs. The reason is that it has a design that works in a two-turntable setup. It also has functions that you will not usually find on belt-drive record players.

In addition, a good direct-drive record player has a slicker design with more bells and whistles. This way, the user can interact with the record player more by manipulating its platter, the spin speed, and even the direction.

On the other hand, belt drive record players differ in how the motor turns the platter. For this reason, people who often opt for belt drive turntables are new record player enthusiasts and audiophiles.

Moreover, belt drives are designed for ease of use and output quality. The reason is that most audiophiles and casual users will not be manipulating the turntable platter while they listen to music. That said, belt-drive turntables usually have little control than direct drive turntables.

Which Turntable Type Should You Get?

If you are new to using a record player, the ideal option is to choose a belt-drive turntable. Apart from being less expensive than direct drive record players, it is also easier to use with less navigation.

In addition, belt-drive turntables are easier to understand the direct drives, especially if you are a newbie. The reason is that this turntable type does not have any buttons. So, beginners will not get confused about which one they should push.

Similarly, music enthusiasts who give so much importance to sound quality should get a belt-drive turntable. The rubber belt absorbs shock, so you will not have to deal with vibration noises.

On the other hand, those who should have a direct drive turntable are DJs. They need to start and stop the music instantaneously and mix two decks, and the quick-start feature will allow them to do such.

Still, it is essential to note that your choice boils down to your preference. (source)

Final Thoughts

Belt-drive record players are ideal for casual music listeners and audiophiles. However, the only problem is that turntable belts can stretch and break over time. But you do not have to worry as you can measure a turntable belt and purchase a new one.

To know the size of the belt you need, you can measure your old rubber belt, the motor, full platter decks, or split platter decks. You also need to measure the width and thickness of the rubber belt that you need.

Additionally, you must know what external factors can damage your record player belt. This way, you will be able to prevent exposure to those factors from happening, thus extending the lifespan of your turntable belt.

- Home Davidson, “10 Tips To Avoid Turntable Trouble,” Popular Mechanics (December 1983) 61.

- Alan Hendrickson, Colin Buckhurst, Mechanical Design for the Stage. USA: Elsevier, 2008.

- “Signs You Might Need a New Turntable Belt,” How to Replace a Turntable Belt (blog). How to Replace a Turntable Belt | Victrola.

- S.P. Bali, Rajeev Bali, Audio Video Systems: Principles, Practices, and Troubleshooting. Khanna Book Publishing Co. (P) Ltd., 2010.

- Danny Briere, Pat Hurley, Home Theater For Dummies. USA: Wiley Publishing, Inc., 2006.

- Jenna Miles, The Beginner’s Guide to Vinyl: How to Build, Maintain, and Experience a Music Collection in Analog. Adams Media, 2017.

VacationVinyl.com is a participant in the Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com. We also participate in other affiliate programs which compensate us for referring traffic.